2025 Top Oil Pumps: The Best Digital Solutions for Efficiency and Performance

In the rapidly evolving landscape of the oil and gas industry, the demand for efficiency and performance in oil pumps has never been more critical. According to the International Energy Agency (IEA), global oil demand is projected to reach 104 million barrels per day by 2025, necessitating advanced technologies to enhance operational efficiency and reduce costs. The integration of digital solutions in oil pump systems is a game-changer for operators aiming to optimize their processes.

Digital oil pumps equipped with smart technologies, such as real-time monitoring and predictive analytics, significantly enhance performance by minimizing downtime and maximizing output. A recent report by Allied Market Research indicates that the global oil pump market is expected to grow at a CAGR of 5.2% from 2020 to 2027, emphasizing the increasing reliance on sophisticated digital solutions in the oil sector. As operators seek to adapt to stringent regulatory demands and sustainability goals, identifying the best-performing oil pumps becomes essential for maintaining competitive advantages and ensuring operational excellence.

This article delves into the top oil pumps for 2025, showcasing the best digital solutions that promise improved efficiency and superior performance, ultimately setting a new standard in the industry.

Innovative Digital Technologies Transforming Oil Pump Efficiency in 2025

In 2025, the oil and gas industry is witnessing a significant transformation driven by innovative digital technologies aimed at enhancing the efficiency and performance of oil pumps. Recent industry reports indicate that the adoption of IoT devices and advanced data analytics is projected to increase operational efficiency by up to 30%. These smart technologies enable real-time monitoring and predictive maintenance, minimizing downtime and optimizing resource allocation, which is crucial in an environment where operational costs are under constant scrutiny.

As companies pivot toward digital solutions, utilizing AI-powered algorithms can effectively forecast equipment failures before they occur, potentially saving the industry billions of dollars. The implementation of machine learning has been reported to improve fault detection rates by over 25%, demonstrating the essential role of these technologies in modern oil pump operations.

Tip: Embrace Predictive Analytics: By investing in predictive maintenance tools, operators can not only foresee issues but significantly reduce the risk of unexpected shutdowns.

As digital technologies continue to evolve, the ability to analyze vast amounts of operational data is becoming imperative. The integration of blockchain for supply chain transparency and secure transactions is projected to enhance trust and efficiency in collaborations across the industry, establishing a new paradigm for oil pump management.

Tip: Optimize Digital Twin Technology: Implementing digital twins for oil pumps allows for simulations that can enhance operational strategies and ultimately lead to better decision-making processes.

Key Performance Metrics for Selecting the Best Oil Pumps in the Digital Era

When choosing the best oil pumps in the digital era, it's essential to focus on key performance metrics that can significantly enhance operational efficiency. Industry reports indicate that factors such as flow rate, energy consumption, and reliability are crucial for assessing pump performance. For instance, pumps that offer variable frequency drive (VFD) capabilities can provide significant energy savings, often reported to reduce energy costs by up to 30% compared to traditional pumps.

Tips: Always consider the total cost of ownership, including maintenance and operational costs, rather than just the initial purchase price. This approach will yield better long-term value for your investment.

Another critical metric is the integration of smart technology. Pumps equipped with IoT capabilities enable real-time monitoring and analytics, allowing for predictive maintenance strategies. According to a recent market analysis, organizations utilizing smart pumps have seen reductions in downtime by approximately 25%.

Tips: Regularly review the software compatibility of your pump systems to ensure seamless integration and maximize data utilization for performance tracking.

Case Studies: Success Stories of Enhanced Performance with Digital Oil Pumps

In the pursuit of enhanced performance and operational efficiency, digital oil pumps are emerging as transformative solutions for the oil and gas industry. Case studies highlighting the successful implementation of these advanced technologies reveal significant gains in productivity and sustainability. Companies utilizing digital oil pumps have reported reductions in energy consumption while maintaining high output levels, aligning with the industry's shift towards more efficient practices.

For instance, one case study demonstrated how a leading oil company integrated digital monitoring systems into their existing pump infrastructure. The implementation not only improved real-time data collection and analysis but also enabled predictive maintenance. This proactive approach minimized downtime and reduced operational costs, showcasing the potential of digital solutions to create a competitive edge while adhering to sustainability goals. By adopting these innovations, organizations can ensure not just immediate improvements in performance but also a more sustainable future for their operations.

Predictive Maintenance: Reducing Downtime and Costs in Oil Pump Operations

Predictive maintenance has emerged as a key strategy in the oil pump industry, significantly reducing both downtime and operational costs. By leveraging advanced digital solutions, companies can monitor the performance and health of their pumps in real-time, allowing for timely interventions before minor issues escalate into major failures. This proactive approach not only minimizes unexpected outages but also enhances overall efficiency in oil pump operations.

The integration of IoT sensors and data analytics plays a crucial role in implementing predictive maintenance. These technologies collect a wealth of information about pump performance, including vibrations, temperature changes, and pressure levels. With sophisticated algorithms analyzing this data, operators can gain valuable insights into wear patterns and potential malfunctions. Consequently, they can schedule maintenance during planned downtimes, thus optimizing operational workflows and significantly lowering costs associated with unplanned repairs and lost production time.

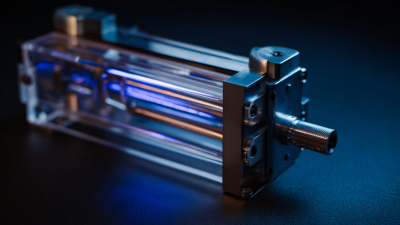

2025 Top Oil Pumps: The Best Digital Solutions for Efficiency and Performance

| Pump Type | Max Flow Rate (GPM) | Efficiency (%) | Maintenance Frequency (Months) | Predictive Maintenance Features |

|---|---|---|---|---|

| Centrifugal Pump | 2500 | 85 | 6 | Real-time monitoring, vibration analysis |

| Positive Displacement Pump | 1500 | 90 | 8 | Pressure monitoring, flow dynamics analysis |

| Submersible Pump | 2000 | 80 | 12 | Temperature monitoring, performance analytics |

| Diaphragm Pump | 1200 | 92 | 9 | Leak detection, flow rate prediction |

Future Trends: The Role of AI and IoT in Revolutionizing Oil Pump Performance

The integration of artificial intelligence (AI) and the Internet of Things (IoT) is set to revolutionize oil pump performance significantly by 2025. Companies in the oil sector are increasingly leveraging AI-driven solutions to enhance efficiency and accuracy in pump operations. These technologies enable real-time monitoring and predictive maintenance, allowing for timely interventions before potential failures occur. By optimizing operational workflows and minimizing downtime, AI is transforming how oil pumps are managed, thus leading to improved productivity and reduced operational costs.

Furthermore, IoT devices allow for seamless data collection from various pump systems across extensive networks. This data can be analyzed using advanced algorithms, generating actionable insights that inform decision-making processes. For instance, data on pump performance and environmental conditions can be used to adjust operations dynamically, ensuring that pumps run at optimal levels under varying circumstances. As these technologies continue to evolve, they are likely to shape the future of oil and gas extraction, making processes smarter, more efficient, and more sustainable.

2025 Top Oil Pumps: Efficiency and Performance Metrics

This chart illustrates the efficiency and performance metrics of various oil pumps in 2025, highlighting the impact of digital solutions and technologies such as AI and IoT.

Related Posts

-

Exploring the Future of Pump for Oil Innovations at the 138th Canton Fair 2025 in China

-

Unlocking Opportunities in Oil Filtration at China's 138th Canton Fair 2025: A Data-Driven Insight

-

What is a Fluid Pump and How Does Its Efficiency Impact Industrial Applications

-

Essential Guide to Choosing the Right Oil and Filter for Your Vehicle's Performance

-

Unlocking Efficiency: The Best 2025 Oil Filter Tools for Every Mechanic's Needs

-

Exploring the Innovations in Fluid Pump Technology and Their Impact on Energy Efficiency