Top 10 Benefits of Using a Pneumatic Pump in Various Applications

In today's fast-paced industrial landscape, the efficiency and reliability of equipment can significantly impact operational success. One solution that has gained remarkable attention is the pneumatic pump, an essential tool for various applications ranging from manufacturing to automotive industries. According to Dr. Emily Johnson, an expert in fluid dynamics and pneumatic systems, "The versatility and efficiency of pneumatic pumps make them indispensable in modern industry, offering solutions that are both cost-effective and environmentally friendly."

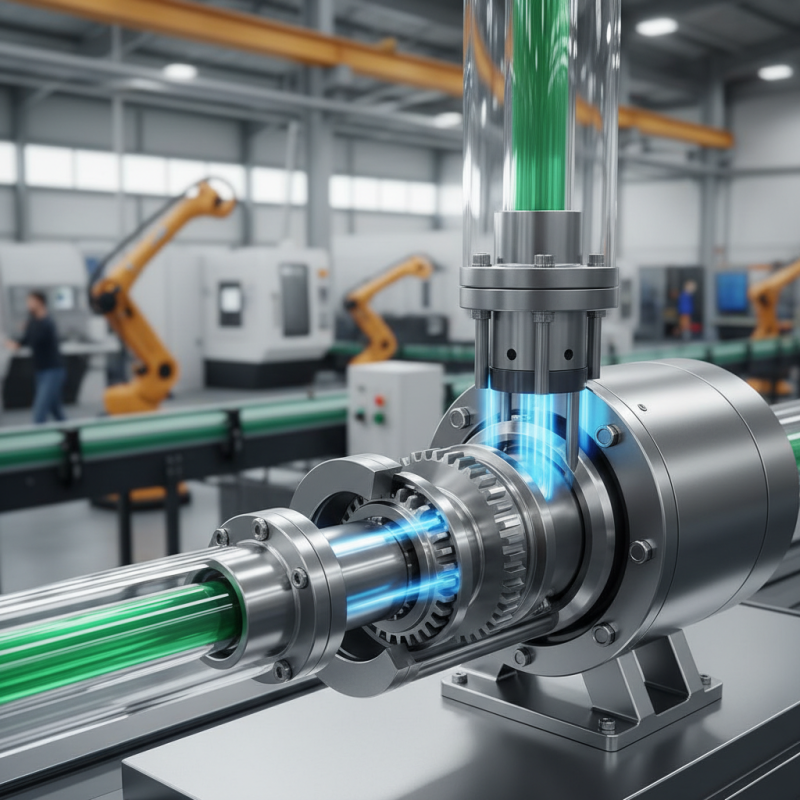

As industries continue to evolve, the demand for energy-efficient and high-performance equipment is paramount. Pneumatic pumps, leveraging compressed air to transport fluids or gases, provide numerous advantages that enhance productivity and streamline processes. Their ability to operate in challenging environments, coupled with their minimal maintenance requirements, positions them as a favored choice among engineers and operators alike.

In this article, we will explore the top ten benefits of using a pneumatic pump across various applications, highlighting their significant contributions to improving efficiency, reducing costs, and ensuring sustainability in industrial operations. By understanding these benefits, businesses can make informed decisions that align with their goals and enhance their operational capabilities.

Advantages of Pneumatic Pumps in Industrial Settings

Pneumatic pumps are invaluable in industrial settings, offering a range of benefits that enhance efficiency and productivity. One major advantage is their reliability in transferring gases and fluids in a variety of applications, from manufacturing to pharmaceuticals. Due to their design, pneumatic pumps can handle volatile or hazardous materials safely, making them ideal for environments where chemical resistance and safety are priorities. Furthermore, they require less maintenance compared to traditional pumps, as they have fewer mechanical parts that can wear out.

When implementing pneumatic pumps, it's important to consider system compatibility. Ensure that your pneumatic system can handle the pressure requirements of your application to maximize efficiency. Additionally, regular maintenance checks can further extend the lifespan of your equipment, ensuring optimal performance.

Another benefit of pneumatic pumps is their ability to operate in extreme environments, such as high temperatures or explosive atmospheres. This makes them ideal for sectors like mining and petrochemicals, where conventional electrical equipment may pose risks. By doing proper research and choosing the right size and type of pneumatic pump, industries can improve their operational safety while fostering a more productive working environment.

Enhanced Efficiency and Performance in Fluid Transfer

Pneumatic pumps have become a vital tool in various industries due to their enhanced efficiency and performance in fluid transfer applications. By utilizing compressed air, these pumps facilitate a smooth and reliable movement of fluids, which is crucial for maintaining productivity and operational efficiency. Their ability to handle a variety of fluids, including corrosive and viscous materials, allows for versatility in applications ranging from manufacturing to construction.

To maximize the performance of pneumatic pumps, it is essential to maintain them properly. Regularly checking for air leaks within the system can significantly improve efficiency, as even minor leaks can lead to increased energy consumption. Additionally, ensuring that the pump is matched correctly to the application requirements can prevent potential operational issues and optimize fluid transfer rates.

Tips for selecting the right pneumatic pump include assessing the specific fluid characteristics, such as viscosity and temperature, as well as understanding the required flow rates for your application. It's also beneficial to consider the environment where the pump will be used—some pneumatic pumps are better suited for harsh conditions than others. By taking these factors into account, users can enhance their processes and achieve superior performance with pneumatic pumps.

Reduced Maintenance Costs Compared to Electric Pumps

Pneumatic pumps have gained recognition in various industrial applications due to their notable advantage of reduced maintenance costs when compared to electric pumps.

According to a recent industry report by the International Society of Automation, pneumatic systems typically require less frequent maintenance, resulting in up to 30% reduction in operational downtime. This is largely attributed to their simpler design, which minimizes the number of mechanically moving parts that could fail or wear out over time. As a result, businesses can allocate resources more efficiently, focusing on production rather than repair.

Moreover, pneumatic pumps operate without the need for electrical components, which significantly cuts down on maintenance expenses. In facilities where electric pumps experience issues, such as overheating or electrical failure, the costs associated with repairs can escalate rapidly. Data from the National Pump Industry Association suggests that companies utilizing pneumatic pumps can save an average of 15%-25% annually on maintenance budgets due to the lower incidence of mechanical failures and the elimination of electrical hazards.

Tips: When considering the transition to pneumatic pumps, it’s essential to assess the specific applications in your facility. Evaluate the air source availability and ensure the compatibility of pneumatic systems with existing processes. Additionally, implementing regular inspections can further enhance the longevity of your pneumatic equipment, providing even more savings in the long run.

Versatility of Pneumatic Pumps Across Multiple Industries

Pneumatic pumps are renowned for their adaptability, making them invaluable across a diverse range of industries. Their ability to deliver high pressure and rapid operation is particularly beneficial in sectors such as manufacturing, construction, and food processing. In manufacturing, pneumatic pumps can efficiently move materials and fluids, ensuring streamlined production lines. The construction industry benefits from their portability and ease of use, enabling quick transfers of concrete, water, or other substances while maintaining safety standards.

Additionally, the versatility of pneumatic pumps extends to the pharmaceutical and automotive sectors. In pharmaceuticals, these pumps can handle delicate substances and ensure precise dosing, crucial for product integrity and compliance with health regulations. Meanwhile, in the automotive industry, pneumatic pumps are integral for applications such as paint spraying and fluid transfer, demonstrating their capacity to enhance efficiency and effectiveness in varied working environments. This adaptability not only maximizes operational performance but also minimizes downtime, proving pneumatic pumps to be a cost-effective solution across multiple applications.

Safety Features and Environmental Benefits of Pneumatic Systems

Pneumatic systems offer significant safety features that contribute to a safer working environment across various applications. One of the primary advantages is their reliance on compressed air, which is inherently non-flammable and non-toxic. This makes pneumatic pumps an excellent choice in environments where the risk of fire or exposure to hazardous liquids is a concern.

Additionally, pneumatic systems are equipped with various protective mechanisms such as pressure relief valves, which prevent system overpressure and potential accidents. These safety features not only protect operators but also enhance overall operational reliability.

Environmental benefits are another critical aspect of pneumatic systems. The use of air as a power source minimizes the risk of contamination, as there are no hazardous fluids being used or spilled. This contributes to cleaner and safer workspaces.

Furthermore, pneumatic systems often consume less energy compared to hydraulic systems, leading to reduced greenhouse gas emissions. As industries continue to focus on sustainability, the adoption of pneumatic technologies aligns with environmental goals, allowing organizations to reduce their carbon footprint while still achieving high efficiency in their operations.

Related Posts

-

Unlocking Clean Air: How Dry Air Filters Enhance Indoor Air Quality and Respiratory Health

-

How to Choose the Right Oil Filter Adapter for Your Vehicle's Needs

-

Harnessing the Power of Tempest Filters for Ultimate Protection in Your Digital Life

-

Exploring the Future of Pump for Oil Innovations at the 138th Canton Fair 2025 in China

-

Understanding the Impact of Advanced Filtration Filters on Water Quality and Health Statistics

-

Exploring the Future of Oil Pumps: Innovations and Efficiency in Modern Machinery