How to Choose the Right Fluid Pump for Your Industrial Needs in 2025

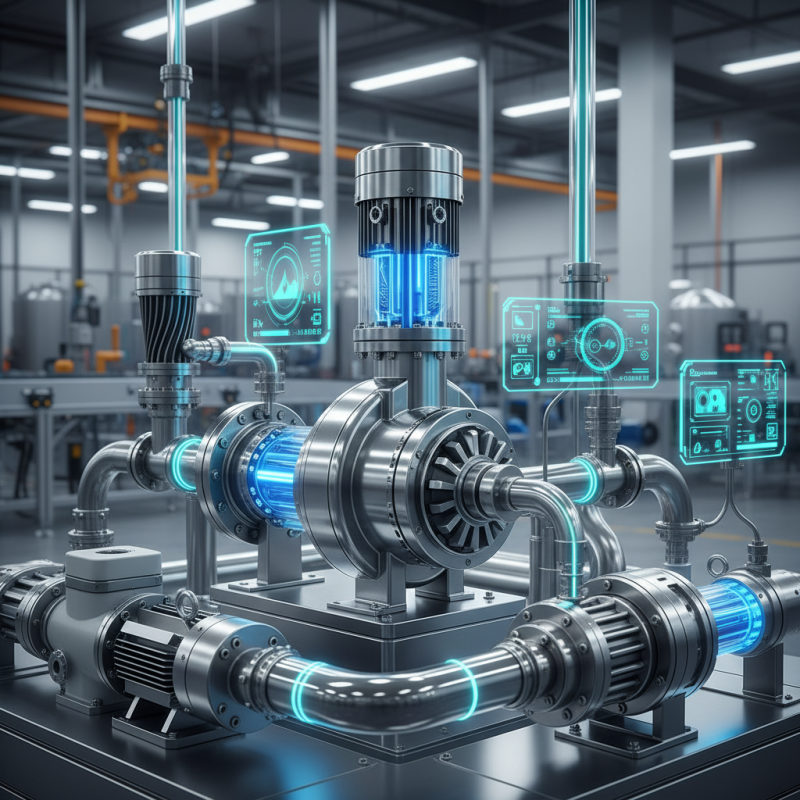

In the ever-evolving landscape of industrial machinery, selecting the right fluid pump is a critical decision for businesses aiming to optimize performance and efficiency. As we step into 2025, advancements in technology and changes in operational requirements make understanding the various types of fluid pumps more important than ever. Fluid pumps are utilized across a wide range of applications, from chemical processing to food and beverage manufacturing, each demanding specific characteristics to ensure safety and reliability.

Choosing the right fluid pump involves more than just evaluating flow rate or pressure; it requires an understanding of the fluid being pumped, the operating environment, and the compatibility of materials used in the pump's construction. In this context, it's essential for industrial operators to consider not only the technical specifications of fluid pumps but also the broader implications of energy consumption, maintenance needs, and overall sustainability. This guide aims to equip decision-makers with the necessary insights to navigate the complexities of fluid pump selection, ensuring that their choices align with both current and future operational goals.

Understanding Different Types of Fluid Pumps Available in 2025

In 2025, industrial sectors will have access to a diverse array of fluid pumps, each designed to serve specific applications and operational requirements. The primary types of fluid pumps include centrifugal pumps, positive displacement pumps, submersible pumps, and diaphragm pumps. According to the latest report from the International Fluid Pump Association, the centrifugal pump market alone is projected to grow by 4.5% annually, driven by its efficiency in transporting large volumes of liquid at relatively low pressures. These pumps are ideal for processes involving water supply, chemical processing, and HVAC applications, making them a go-to choice across various industries.

Positive displacement pumps, on the other hand, have gained traction due to their capability to handle viscous fluids and maintain consistent flow rates, even against varying pressures. This makes them indispensable in sectors like oil and gas, where the demand for robustness and reliability is paramount. The North American Pump Market Report estimates that the positive displacement segment will increase by 5.2% within the next five years, largely owing to innovations in manufacturing and the growing need for automated systems to improve operational efficiency. As industries evolve toward more sustainable and energy-efficient practices, understanding these fluid pump types will be crucial in selecting the right equipment that meets both current and future demands.

How to Choose the Right Fluid Pump for Your Industrial Needs in 2025

| Pump Type | Applications | Flow Rate (GPM) | Pressure Range (PSI) | Material Compatibility |

|---|---|---|---|---|

| Centrifugal Pump | Water transfer, Chemical processing | 10 - 500 GPM | 30 - 150 PSI | Chemicals, Water |

| Positive Displacement Pump | Viscous liquids, Oil transfer | 5 - 200 GPM | 50 - 200 PSI | Oils, Resins |

| Diaphragm Pump | Chemical dosing, Sludge transfer | 1 - 50 GPM | 0 - 120 PSI | Acids, Slurries |

| Gear Pump | Fuel transfer, Hydraulic systems | 2 - 100 GPM | 50 - 250 PSI | Petroleum, Light oils |

| Submersible Pump | Water extraction, Wastewater management | 20 - 300 GPM | 10 - 100 PSI | Water, Sewage |

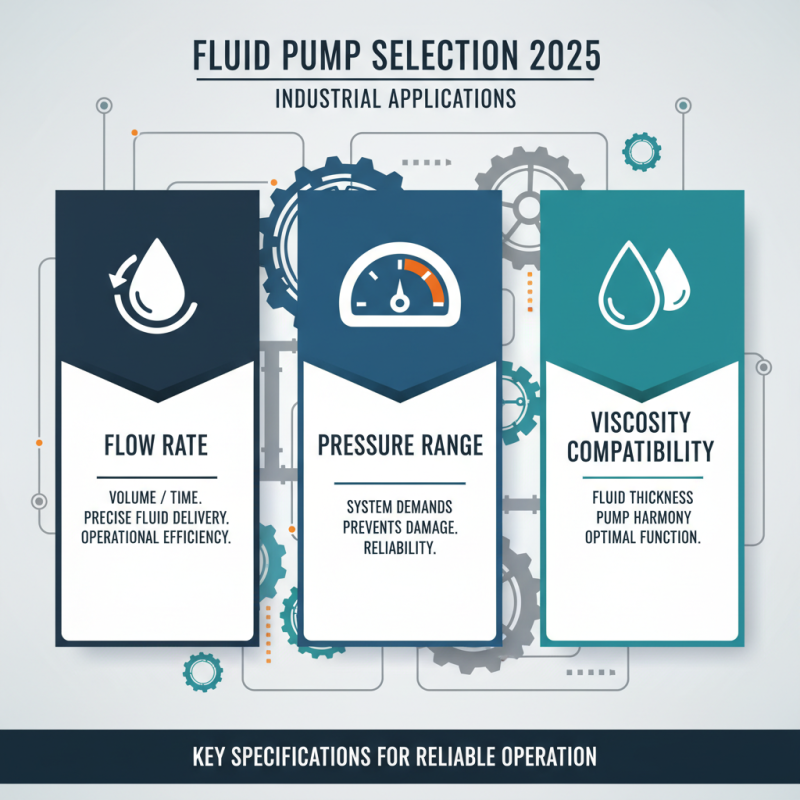

Evaluating Performance Specifications for Your Industrial Applications

When selecting a fluid pump for industrial applications in 2025, evaluating performance specifications is critical to ensuring operational efficiency and reliability. Key specifications to consider include flow rate, pressure range, and viscosity compatibility. The flow rate determines how much fluid can be delivered over time, which is essential for processes requiring precise fluid management. Meanwhile, the pressure range ensures that the pump can operate effectively within the operational demands of the system without risking damage or inefficiencies.

Additionally, understanding the fluid's viscosity is paramount, as it influences the pump's ability to maintain consistent flow and minimize wear. Different types of pumps are designed to handle varying viscosities, and selecting the appropriate type can make a significant difference in performance and maintenance costs. Furthermore, examining the materials of construction is vital to prevent corrosion and degradation, especially in applications involving aggressive media. Tailoring your pump choice to these specifications will not only optimize performance but also enhance the longevity of your equipment in challenging industrial environments.

Identifying Compatibility with Fluids and Operating Conditions

When selecting a fluid pump for industrial applications in 2025, it's essential to ensure compatibility with the specific fluids being handled as well as the operating conditions of the environment. The type of fluid—whether it is corrosive, viscous, or contains particulates—will directly influence the choice of pump materials and design. For example, if the fluid is highly corrosive, pumps made of specialized materials such as stainless steel or certain alloys should be considered to prolong the lifespan of the equipment. Additionally, the properties of the fluid, including its viscosity, temperature, and specific gravity, will determine the pump type that can effectively transfer the fluid without causing damage or operational inefficiency.

Operating conditions further complicate the selection process. Factors such as ambient temperatures, pressure ratings, and the possibility of exposure to various substances in the environment must be assessed carefully. High-temperature applications may require pumps with enhanced thermal resistance, while environments with a high risk of contamination may benefit from sanitary designs that are easier to clean and maintain. Furthermore, understanding the operational demands, such as flow rates and cycles, is vital for ensuring that the pump can meet the specific requirements of the system. By prioritizing compatibility with both the fluid handled and the operating conditions, industrial operators can make informed decisions that enhance efficiency and reliability in their processes.

Assessing Energy Efficiency and Cost Considerations

When selecting a fluid pump for industrial applications in 2025, energy efficiency and cost considerations are paramount. The evolving landscape of regulations and standards surrounding energy consumption means that businesses must prioritize pumps that not only meet their operational requirements but also align with sustainability goals. High-efficiency pumps can significantly reduce energy expenses over their lifecycle, making them a more economically viable choice. Additionally, the long-term savings on utility bills can offset the initial investment costs, thereby enhancing financial sustainability.

Moreover, cost considerations extend beyond just the purchase price of the pump. Maintenance and operational costs are crucial factors that facility managers should evaluate. A pump that requires frequent repairs or has a higher likelihood of failure may lead to increased downtime and additional expenditures. Choosing models with robust design features that minimize wear and tear can prove beneficial in reducing maintenance needs and extending service life. Therefore, a comprehensive analysis that encompasses both energy efficiency and total cost of ownership will empower organizations to make informed decisions that best suit their industrial fluid management needs.

Energy Efficiency and Cost Comparison of Fluid Pumps (2025)

Exploring Maintenance and Support Services for Long-Term Use

When selecting a fluid pump for industrial applications, understanding the maintenance and support services available is crucial for ensuring long-term performance and reliability. According to a recent report by the Fluid Power Industries Association, approximately 30% of pump failures can be traced back to inadequate maintenance. This underlines the importance of not just choosing the right pump, but also engaging a robust maintenance strategy that incorporates regular inspections, calibration, and timely repairs.

Establishing a proactive maintenance plan can significantly extend the lifespan of a fluid pump. The best practices include scheduling routine check-ups, utilizing predictive maintenance technologies, and training personnel on troubleshooting techniques. Research indicates that companies that implement scheduled maintenance can reduce their overall operational costs by up to 25%, as preventive measures decrease the likelihood of unexpected equipment failures. Furthermore, partnering with experienced support service providers enables businesses to gain insights into the latest maintenance technologies and best practices, ensuring optimal pump performance in the long run.

Investing in support services such as training programs and access to specialized technical knowledge not only enhances the operational efficiency of fluid pumps but also fosters a culture of continuous improvement within the organization. In fact, an industry survey revealed that businesses with structured maintenance and support frameworks reported a 15% increase in productivity. As such, aligning your pump selection process with comprehensive maintenance strategies could be the key to maximizing the return on investment in industrial fluid systems.

Related Posts

-

Exploring the Latest Innovations in Fluid Pump Technology for Enhanced Efficiency

-

What is a Fluid Pump and How Does Its Efficiency Impact Industrial Applications

-

Exploring the Future of Oil Pumps: Innovations and Efficiency in Modern Machinery

-

Harnessing the Power of Tempest Filters for Ultimate Protection in Your Digital Life

-

Unlocking Opportunities in Oil Filtration at China's 138th Canton Fair 2025: A Data-Driven Insight

-

How to Choose the Best Dry Air Filter for Your Home and Office Needs