Top 7 Common Problems with Fuel Oil Filters and How to Fix Them

In the realm of heating systems and fuel management, the importance of a reliable fuel oil filter cannot be overstated. According to a recent report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper filtration can lead to over 30% of equipment failures in heating systems, which emphasizes the critical role of maintaining clean and functional fuel oil filters. Expert James D. Henderson, a veteran in the fuel technology sector, notes, "Ignoring the maintenance of fuel oil filters incurs unnecessary costs and risks inefficiency in fuel utilization."

Despite their vital function, fuel oil filters are often subjected to common issues that can significantly impair performance. These problems not only affect the efficiency of heating systems but can also result in increased operational costs and environmental impact. Understanding and rectifying these common issues can enhance both the lifespan of the heating equipment and the quality of air inside homes and industrial spaces. As the industry strives for improved energy efficiency and sustainability, addressing the limitations in fuel oil filter systems becomes paramount for both operators and consumers alike, making it essential to explore the top challenges and their solutions in the context of fuel oil filtration.

Understanding the Function of Fuel Oil Filters in Equipment

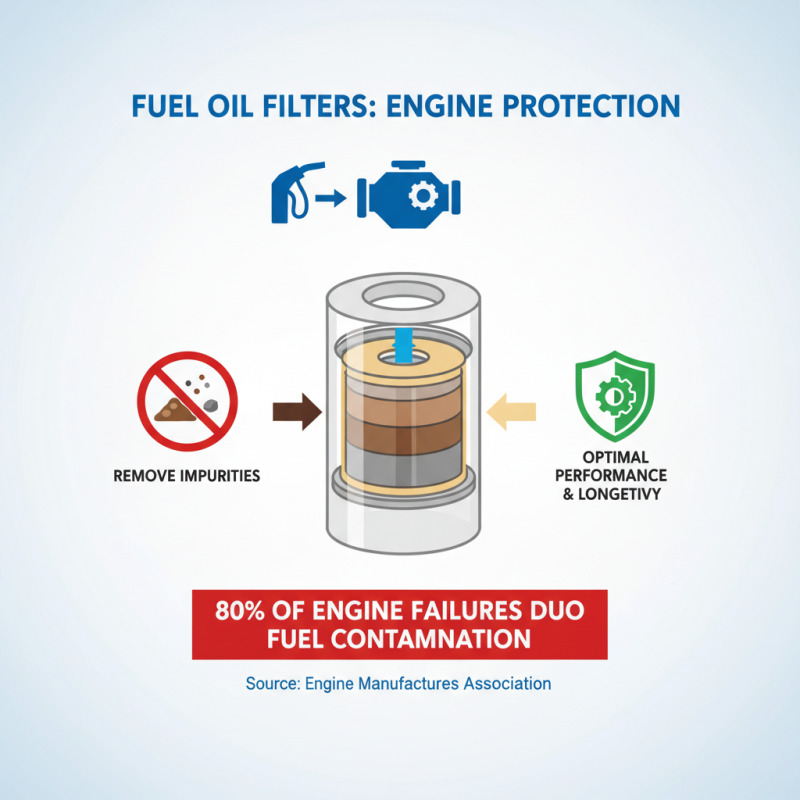

Fuel oil filters are pivotal components in the operation of various machinery, as they play a crucial role in maintaining the integrity and performance of fuel systems. These filters are designed to remove impurities, such as dirt, rust, and sediment, from the fuel before it enters the engine or burner. According to a report by the Engine Manufacturers Association, up to 80% of engine failures can be attributed to fuel contamination. This statistic underscores the importance of ensuring that fuel oil filters are functioning optimally to protect equipment longevity and performance.

In industrial settings, where heavy machinery operates under demanding conditions, the need for reliable fuel oil filtration becomes even more critical. A study by the National Renewable Energy Laboratory highlights that inadequate filtration can lead to increased wear and tear on engine components, resulting in higher maintenance costs and unexpected downtime. Regular inspection and replacement of fuel oil filters are essential practices recommended by industry experts. By maintaining clean filtration systems, operators can significantly reduce the risk of equipment failure and extend the lifespan of their machinery, thus ensuring efficient and cost-effective operations.

Common Symptoms of Fuel Oil Filter Failures

Fuel oil filters play a crucial role in ensuring that the fuel fed into a system is clean and free from contaminants. When these filters start to fail, several symptoms can manifest, signaling the need for immediate attention. One of the most common signs of a failing fuel oil filter is reduced engine performance. This can include difficulties in starting, rough idling, or stalling, which indicate that the fuel supply may be obstructed due to a clogged filter.

Another significant symptom to watch for is the presence of black smoke coming from the exhaust. This can happen when the engine is not receiving enough clean fuel, leading to incomplete combustion. Additionally, if you notice frequent fuel leaks or a drop in fuel pressure, these could also be indicators of filter issues. Addressing these symptoms promptly can help prevent further damage to the engine and ensure optimal performance of the heating or fueling system. Regular maintenance and timely replacement of fuel oil filters can mitigate such problems and prolong the life of the equipment.

Step-by-Step Troubleshooting for Clogged Fuel Oil Filters

Clogged fuel oil filters can significantly hinder the efficiency of heating systems and engines. A common symptom of this issue is reduced fuel flow, which can lead to poor combustion and increased emissions. According to industry reports, approximately 30% of heating system failures are attributed to fuel filter problems, making troubleshooting essential for maintaining system performance.

When addressing clogged fuel oil filters, the first step is to isolate the problem by examining the fuel flow rate. If the flow is below the manufacturer’s specifications, it indicates a blockage. Cleaning or replacing the filter can often resolve this issue. Additionally, inspecting for any debris in the fuel line and using a fuel cleaner can help prevent future clogs.

Tip: Regular maintenance of the fuel system, including periodic filter changes based on usage and environmental conditions, can save time and costs in the long run. It's generally recommended to replace fuel filters every 6 to 12 months, especially in areas prone to high sediment levels.

Moreover, ensuring that the storage tank is clean can reduce the risk of clogging. If the problem persists, check for water contamination, which is a common culprit in oil filter issues. Water can not only cause clogging but also bacterial growth, leading to further complications.

Tip: Implementing a filtration system that captures larger particles before they reach the filter can enhance overall filtration efficiency and prolong filter life.

Maintenance Tips to Prevent Fuel Oil Filter Problems

Proper maintenance of fuel oil filters is crucial for ensuring the efficiency and longevity of heating systems. Regular inspection and replacement of filters can prevent common issues such as clogging and fuel contamination, which, according to the U.S. Department of Energy, can lead to a decrease in system performance by up to 30%. Implementing a routine maintenance schedule can significantly mitigate these risks. It is recommended that filters be checked and replaced at least once a year or more frequently if your system experiences high usage or operates in a particularly dusty environment.

In addition, keeping the fuel storage tank clean can minimize the likelihood of sediment buildup that clogs filters. The National Oilheat Research Alliance suggests that having a professional perform annual tank cleaning can further ensure that your fuel oil remains uncontaminated. Utilizing a water separator can also help in preventing moisture accumulation in stored oil, which is essential since water is a primary reason for filter failure. Maintaining proper fuel supply and employing appropriate filtration media can enhance filter lifespan while improving overall system efficiency. Regular preventative measures not only save costs in repair but also contribute to a more efficient energy use, aligning with the latest industry standards for optimal heating performance.

Top 7 Common Problems with Fuel Oil Filters and How to Fix Them

| Problem | Description | Solution | Prevention Tips |

|---|---|---|---|

| Clogged Filter | Excessive debris accumulation leads to reduced flow. | Replace the filter regularly. | Inspect and clean the system periodically. |

| Water Contamination | Water in fuel can lead to corrosion and microbial growth. | Use a water separator and test fuel regularly. | Store fuel in a dry environment. |

| Leaking Filter | Cracks or faulty seals lead to oil leaks. | Replace faulty filters immediately. | Check seals and gaskets periodically. |

| Air Leaks | Air in the fuel system can cause poor performance. | Inspect and replace damaged lines. | Ensure all connections are secure. |

| Fungus Growth | Microbial growth can block filters and damage systems. | Use biocides in the fuel to eliminate growth. | Regularly treat and inspect fuel quality. |

| Incorrect Filter Size | Using the wrong filter can restrict flow. | Always verify filter specifications before installation. | Maintain proper records of filter types used. |

| Temperature Issues | Extreme temperatures can affect filter performance. | Use filters rated for the expected temperature range. | Insulate fuel lines if necessary. |

When to Replace Your Fuel Oil Filter: Signs to Watch For

When it comes to maintaining efficient fuel oil systems, knowing when to replace your fuel oil filter is crucial. One of the first signs to watch for is a noticeable decrease in performance. If your heater or engine begins to sputter, work harder than usual, or take longer to warm up, it may indicate that the filter is clogged and restricting the flow of fuel. Additionally, frequent cycling of the heating system or irregular operation can suggest that the filter is struggling to provide clean fuel.

Another significant indicator of a failing filter is the presence of contaminated fuel. If you notice a change in the color or clarity of the oil, with a murky or dark appearance, this can signal that the filter is unable to trap sediments and impurities effectively. Routine checks for leaks around the fuel filter area or signs of engine misfires can also indicate that it's time for a replacement. Regular inspections and awareness of these signs can help ensure a smooth operation and prolong the life of your fuel oil system.

Related Posts

-

Unlocking Clean Air: How Dry Air Filters Enhance Indoor Air Quality and Respiratory Health

-

Why You Need Spark Plug Tools for Effective Engine Maintenance

-

How to Choose the Right Fluid Pump for Your Industrial Needs in 2025

-

Exploring the Future of Oil Pumps: Innovations and Efficiency in Modern Machinery

-

Top 10 Benefits of Using a Pneumatic Pump in Various Applications

-

What is a Fluid Pump and How Does Its Efficiency Impact Industrial Applications