How to Diagnose and Troubleshoot Common Fuel Pump Problems

In the realm of automotive maintenance and repair, fuel pumps play a pivotal role in ensuring the efficient operation of combustion engines. According to industry data, approximately 60% of fuel system issues stem from malfunctioning fuel pumps, highlighting their significance in vehicle performance. As vehicles continue to become more sophisticated, equipped with advanced fuel management systems, understanding the common problems associated with fuel pumps is crucial for both mechanics and vehicle owners alike.

Diagnosing fuel pump problems can be challenging, as symptoms often mimic other fuel system malfunctions. For instance, irregular engine behavior, poor fuel economy, and difficulty starting the vehicle can all originate from a failing fuel pump. Reports suggest that timely diagnosis and troubleshooting can save vehicle owners an average of $500 in unnecessary repairs, underscoring the importance of early detection. As technology advances, the complexity of fuel pump systems also increases, making it vital for professionals to stay informed about the latest diagnostic techniques and troubleshooting strategies. This article aims to provide insights into common fuel pump problems and effective methods for diagnosing and resolving these issues.

Understanding the Role of Fuel Pumps in Vehicle Performance

Fuel pumps are critical components in vehicle performance, as they ensure a consistent flow of fuel from the tank to the engine. A malfunctioning fuel pump can lead to poor engine performance, stalling, and even complete failure to start. According to the Automotive Aftermarket Industry Association (AAIA), fuel pumps account for approximately 15% of all vehicle repair requests, indicating that they are a common point of failure in modern vehicles. Understanding how fuel pumps function and recognizing their importance is key to maintaining optimal vehicle performance.

In a study by the National Highway Traffic Safety Administration (NHTSA), over 20% of vehicle breakdowns were attributed to fuel delivery issues, most often related to the fuel pump. These issues can stem from factors such as clogged filters, electrical failures, or wear and tear over time. Regular maintenance and timely replacement can mitigate these problems, ensuring that the fuel pump operates efficiently. By recognizing the signs of a failing fuel pump— such as decreased fuel efficiency, unusual noises, or changes in acceleration— drivers can take proactive steps to diagnose and troubleshoot potential issues before they lead to more significant complications.

How to Diagnose and Troubleshoot Common Fuel Pump Problems

| Problem | Symptoms | Possible Causes | Troubleshooting Steps | Solution |

|---|---|---|---|---|

| No Start | Engine cranks but doesn't start | Failed fuel pump, clogged filter | Check for fuel pressure, inspect fuel pump fuse | Replace fuel pump or filter |

| Stalling | Engine cuts out while driving | Intermittent pump failure | Check fuel delivery and pump operation | Repair or replace faulty components |

| Low Power | Reduced engine performance, sluggish acceleration | Restricted fuel flow from blockages | Inspect fuel lines for clogs, check pump operation | Clean or replace filters and lines |

| Noisy Pump | Loud whining or humming noise | Worn bearings or low fuel level | Listen for noise, check fuel levels | Replace pump if noise persists |

| Vibration | Vibrations felt in vehicle | Improper installation or worn mounts | Inspect pump mounting and alignment | Reinstall or replace mounts as needed |

Identifying Symptoms of Fuel Pump Malfunctions

When it comes to diagnosing and troubleshooting fuel pump problems, identifying the symptoms of malfunctions is crucial for timely intervention. A common indication of a failing fuel pump is difficulty starting the engine or stalling during operation. According to a report by the Automotive Service Association, approximately 60% of fuel pump failures are preceded by noticeable performance symptoms, such as reduced engine power or unusual noises emanating from the fuel tank.

Additionally, irregular fuel pressure can be a telltale sign of a malfunctioning fuel pump. The Automotive Research Center indicates that maintaining the correct fuel pressure is essential for optimal engine performance, and deviations from the manufacturer’s specifications can lead to serious engine issues. Symptoms may include engine misfires or poor acceleration, which often leads drivers to confuse these issues with other components.

Spotting these signs early can save time and expenses related to extensive repairs, underscoring the importance of regular vehicle maintenance checks focused on the fuel system.

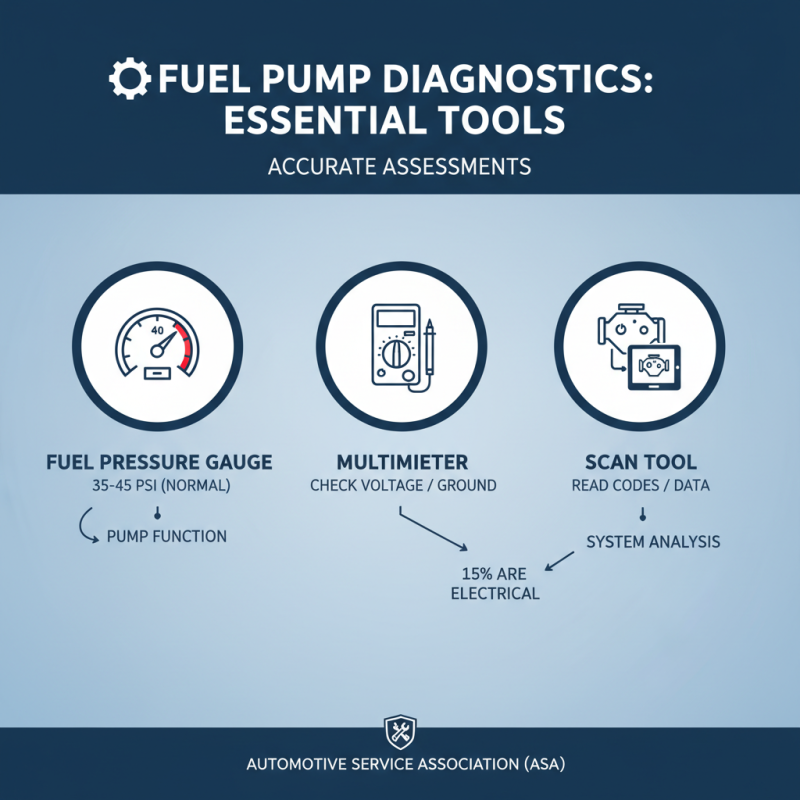

Key Diagnostic Tools for Fuel Pump Troubleshooting

Diagnosing and troubleshooting fuel pump problems can be a daunting task, but having the right diagnostic tools is essential for accurate assessments. Key tools such as a fuel pressure gauge, multimeter, and a scan tool are indispensable in this process. According to the Automotive Service Association (ASA), approximately 15% of fuel pump failures can be traced back to electrical issues, making a multimeter vital for checking voltage and ground connections to the pump. Proper fuel pressure readings, typically between 35-45 PSI for most vehicles, can reveal whether the pump is functioning within its specifications.

Tips: Regular maintenance checks should include tests of your fuel pump's electrical connections and fuel pressure levels. Keeping a fuel pressure gauge on hand allows for easy monitoring and can help detect issues before they escalate.

In addition to these tools, a scan tool can provide invaluable insights into the vehicle's onboard diagnostics. The National Institute for Automotive Service Excellence (ASE) emphasizes that many modern fuel pump issues can be linked back to engine control unit (ECU) malfunctions. Therefore, utilizing a scan tool to check for any trouble codes related to the fuel system is a proactive step towards effective troubleshooting. Understanding these tools can significantly streamline the diagnostic process and enhance vehicle reliability.

Common Fuel Pump Failure Modes and Their Causes

Common fuel pump failure modes can significantly impact vehicle performance, making it essential to understand their underlying causes. One prevalent issue is fuel pump wear due to prolonged use, which can lead to inadequate fuel delivery. This often arises from running the vehicle with a low fuel level regularly, causing the pump to overheat and wear out prematurely. Additionally, contamination from dirt and debris in the fuel tank can block the pump or its filters, further degrading its efficiency.

Another common failure mode is electrical malfunction, often linked to blown fuses or faulty wiring. A damaged relay can also prevent the pump from receiving adequate power, leading to starting issues or a complete inability to run the engine. Another cause of pump failure is excessive pressure or an obstruction in the fuel lines, which can result from a clogged fuel filter or damaged fuel injectors. By diagnosing these failure modes and understanding their origins, vehicle owners can take proactive measures to maintain their fuel systems effectively.

Common Fuel Pump Failure Modes and Their Causes

Steps to Test and Replace a Defective Fuel Pump

When diagnosing and troubleshooting fuel pump issues, the first step is to conduct a series of tests to determine whether the pump is functioning correctly. Start by checking the fuel pump relay and fuse, as these can often be the culprits in fuel delivery problems. If the relay and fuse are intact, utilize a multimeter to measure the voltage at the fuel pump connector while the ignition is turned on. A reading of approximately 12 volts indicates that the pump is receiving power, while a lack of voltage suggests a potential electrical issue.

If the pump is receiving power but still not operating, it may be time for replacement. Begin by relieving the fuel system pressure to ensure safety, and then locate the fuel pump, typically found within the fuel tank. Disconnect the fuel lines and electrical connectors before removing the mounting hardware. Install the new pump by following the reverse process, ensuring all connections are secure. Finally, recheck for leaks and test the vehicle to confirm that fuel delivery issues have been resolved.

Related Posts

-

What is a Fluid Pump and How Does Its Efficiency Impact Industrial Applications

-

Exploring the Future: How New Fuel Innovations Can Transform Our Energy Landscape

-

Essential Guide to Choosing the Right Oil and Filter for Your Vehicle's Performance

-

Unlocking Opportunities in Oil Filtration at China's 138th Canton Fair 2025: A Data-Driven Insight

-

How to Choose the Right Oil Filter Adapter for Your Vehicle's Needs

-

What are Spark Plugs and How Do They Impact Your Engine's Performance?