Exploring the Future of Oil Pumps: Innovations and Efficiency in Modern Machinery

In the dynamic landscape of the oil industry, the demand for efficient and reliable machinery is greater than ever. As we delve into the future of oil pumps, particularly focusing on the "pump for oil", it is essential to highlight the transformative innovations shaping this sector. According to a recent report by Allied Market Research, the global oil pump market is projected to grow at a CAGR of 5.2% from 2021 to 2028, driven by advancements in technology and a heightened emphasis on operational efficiency.

Furthermore, the integration of smart technologies, such as IoT and AI, is revolutionizing traditional pumping systems, increasing their efficiency and performance. By leveraging these advancements, modern oil pumps not only meet the rigorous demands of extraction and transportation but also contribute to sustainability efforts within the industry. This exploration will illuminate the crucial role of innovations in oil pump technology and their implications for the industry's future.

Understanding the Evolution of Oil Pump Technology and Its Impact on Efficiency

The evolution of oil pump technology has significantly influenced overall efficiency in the machinery sector. Historically, traditional oil pumps faced challenges with energy loss and material degradation, often leading to decreased performance and higher maintenance costs. According to a recent report by the International Energy Agency, advancements in pump design and materials have resulted in efficiency gains of up to 30% in modern systems. Innovations such as smart sensors and IoT integration allow for real-time monitoring and predictive maintenance, minimizing downtime and enhancing operational reliability.

The evolution of oil pump technology has significantly influenced overall efficiency in the machinery sector. Historically, traditional oil pumps faced challenges with energy loss and material degradation, often leading to decreased performance and higher maintenance costs. According to a recent report by the International Energy Agency, advancements in pump design and materials have resulted in efficiency gains of up to 30% in modern systems. Innovations such as smart sensors and IoT integration allow for real-time monitoring and predictive maintenance, minimizing downtime and enhancing operational reliability.

Tips: When selecting an oil pump, consider the compatibility of materials with the fluid being pumped to reduce wear and extend lifespan. Additionally, investing in energy-efficient pumps can reduce operational costs significantly over time.

Another key aspect of this evolution is the shift towards environmentally friendly technologies. The latest oil pumps are designed to reduce emissions and minimize waste, aligning with global sustainability goals. According to a 2023 report by the American Society of Mechanical Engineers, the adoption of variable frequency drives in oil pumps has increased energy efficiency by an average of 25%, showcasing how technology can drive both performance and eco-friendliness.

Tips: Regularly maintaining your oil pumps ensures optimal performance and extends their operational life, while also reducing the environmental impact of your machinery.

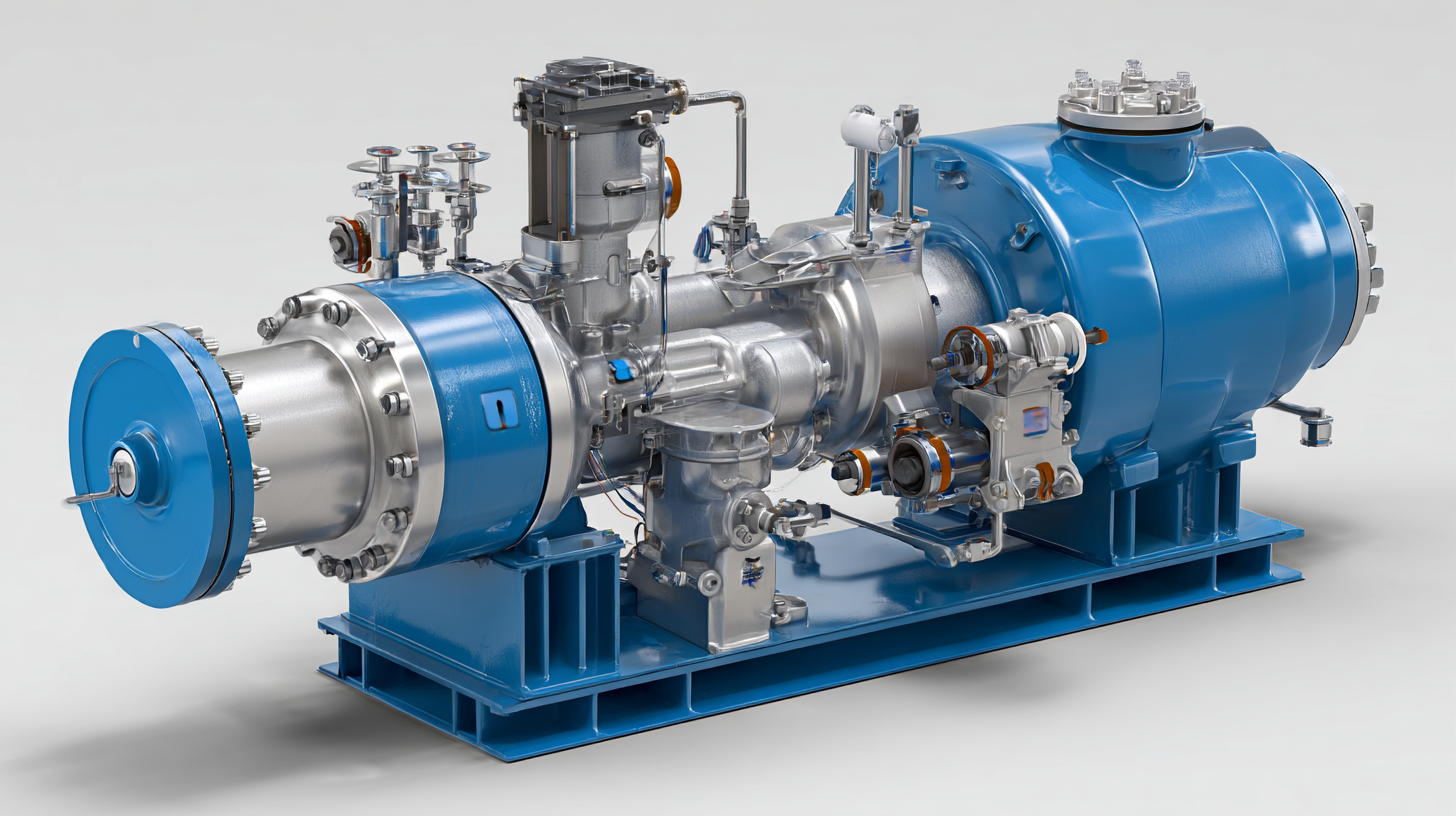

Innovative Designs: How Modern Oil Pumps Enhance Performance and Reliability

Modern oil pumps have undergone a significant transformation, driven by innovative designs that enhance both performance and reliability. One of the hallmark advancements is the integration of smart technology, which allows for real-time monitoring and diagnostics. These intelligent systems can predict failures before they occur, minimizing downtime and maintenance costs. Additionally, the use of advanced materials facilitates lighter and more durable designs that improve efficiency, thus catering to the increasingly demanding requirements of various industries.

Another key innovation in modern oil pump design is the implementation of variable speed drives. This technology enables pumps to adjust their operational speed based on the specific needs of the system, enhancing energy efficiency and reducing wear and tear. Furthermore, optimized hydraulic designs improve the flow patterns within the pumps, resulting in reduced turbulence and energy losses. These enhancements culminate in oil pumps that not only deliver superior performance but also align with environmental standards by lowering energy consumption and minimizing emissions.

Exploring the Future of Oil Pumps: Innovations and Efficiency in Modern Machinery

| Innovative Features | Efficiency Rating (%) | Flow Rate (L/min) | Material Used | Maintenance Interval (months) |

|---|---|---|---|---|

| Smart Monitoring System | 92 | 500 | Aluminum Alloy | 12 |

| Variable Frequency Drive | 89 | 450 | Stainless Steel | 10 |

| Self-Priming Capability | 85 | 400 | Composites | 8 |

| Noise Reduction Technology | 90 | 600 | Cast Iron | 15 |

| Energy Recovery Systems | 95 | 550 | Titanium | 20 |

Assessing Energy Efficiency: Best Practices for Optimal Oil Pump Operation

In the ever-evolving landscape of oil pump technology, energy efficiency has become a prime focus. With rising energy costs and environmental concerns, optimizing oil pump operation is essential for both sustainability and cost-effectiveness. To achieve this, operators should adopt best practices tailored to modern machinery, ensuring that every pump run is as efficient as possible.

**Tips:** Regularly maintain your oil pumps to prevent any mechanical issues that can lead to energy wastage. Implementing a scheduled maintenance program can identify and resolve inefficiencies before they escalate, ensuring your equipment operates at peak performance.

Incorporating advanced control systems can also significantly enhance the efficiency of oil pump operations. These systems can monitor real-time data, allowing for quick adjustments based on demand and environmental conditions. Moreover, transitioning to variable speed drives can fine-tune pump performance, reducing energy consumption during lower demand periods.

**Tips:** Consider investing in training for your team on energy-efficient practices and technologies. Well-informed operators are crucial for maximizing the potential of both the machinery and the overall system, leading to improved energy savings and operational longevity.

Integrating Smart Technology: The Role of IoT in Future Oil Pump Systems

The integration of smart technology into oil pump systems is set to revolutionize the industry. With the advent of the Internet of Things (IoT), oil pumps can now communicate seamlessly with other machinery and monitoring systems. This interconnectedness allows for real-time data collection and analysis, enabling operators to optimize performance and predict maintenance needs before they escalate into costly failures. Imagine a scenario where an oil pump not only measures output and efficiency but also sends alerts regarding potential issues, helping to minimize downtime.

Tips: When considering the implementation of IoT in oil pump systems, focus on the compatibility of existing machinery with new technology. Ensure that all devices can communicate effectively with centralized management systems for seamless data integration.

Furthermore, smart oil pump systems can adapt to environmental changes and operational demands through AI algorithms. These algorithms learn from historical data, allowing the system to adjust its operations dynamically to maximize efficiency and reduce energy consumption. As a result, companies can achieve significant cost savings while also contributing to sustainability efforts.

Tips: Regularly update your IoT software and device firmware. Maintaining the latest versions can enhance security and ensure optimal functionality for your oil pump systems.

Sustainability in Oil Pump Manufacturing: Strategies for Reducing Environmental Impact

The oil pump manufacturing industry is undergoing significant transformation as companies strive to adopt more sustainable practices. Key strategies include the utilization of eco-friendly materials that reduce the overall carbon footprint during the production process. By sourcing sustainable raw materials and implementing recycling initiatives, manufacturers can minimize waste and enhance the circular economy associated with oil pump production. This not only benefits the environment but also appeals to increasingly eco-conscious consumers and industries.

Moreover, technological advancements play a crucial role in enhancing the energy efficiency of oil pumps. Innovations such as smart monitoring systems and advanced materials contribute to reduced energy consumption during operation. These systems not only improve performance but also allow for predictive maintenance, which minimizes downtime and resource use. By integrating sustainability into design and manufacturing processes, the industry can significantly lower its environmental impact while maintaining high standards of functionality and efficiency in modern machinery.

Related Posts

-

Exploring the Future of Pump for Oil Innovations at the 138th Canton Fair 2025 in China

-

Unlocking Opportunities in Oil Filtration at China's 138th Canton Fair 2025: A Data-Driven Insight

-

Unlock Your Engine's Potential: The Ultimate Guide to Choosing the Right Spark Plugs

-

Unlocking Fuel Oil: Understanding Its Importance and Impact on Today's Energy Landscape

-

What are Spark Plugs and How Do They Impact Your Engine's Performance?

-

Exploring the Future: How New Fuel Innovations Can Transform Our Energy Landscape