Exploring the Innovations in Fluid Pump Technology and Their Impact on Energy Efficiency

The advancement of fluid pump technology is revolutionizing various industries by enhancing energy efficiency and operational effectiveness. According to a report by the U.S. Department of Energy, up to 20% of the total electricity consumption in industrial and commercial sectors is attributed to pump systems, highlighting the critical role that fluid pumps play in energy usage. With innovations such as variable frequency drives, smart pumps, and advanced materials, the pump industry is witnessing transformative changes that not only reduce energy consumption but also lower operational costs. A study by the Hydraulic Institute indicates that implementing modern fluid pump technologies can lead to energy savings of 30% or more, emphasizing the potential for significant environmental and economic benefits. This article will delve into these innovations in fluid pump technology and explore their far-reaching impact on energy efficiency across different applications.

Innovations Transforming Fluid Pump Efficiency: A Comprehensive Overview

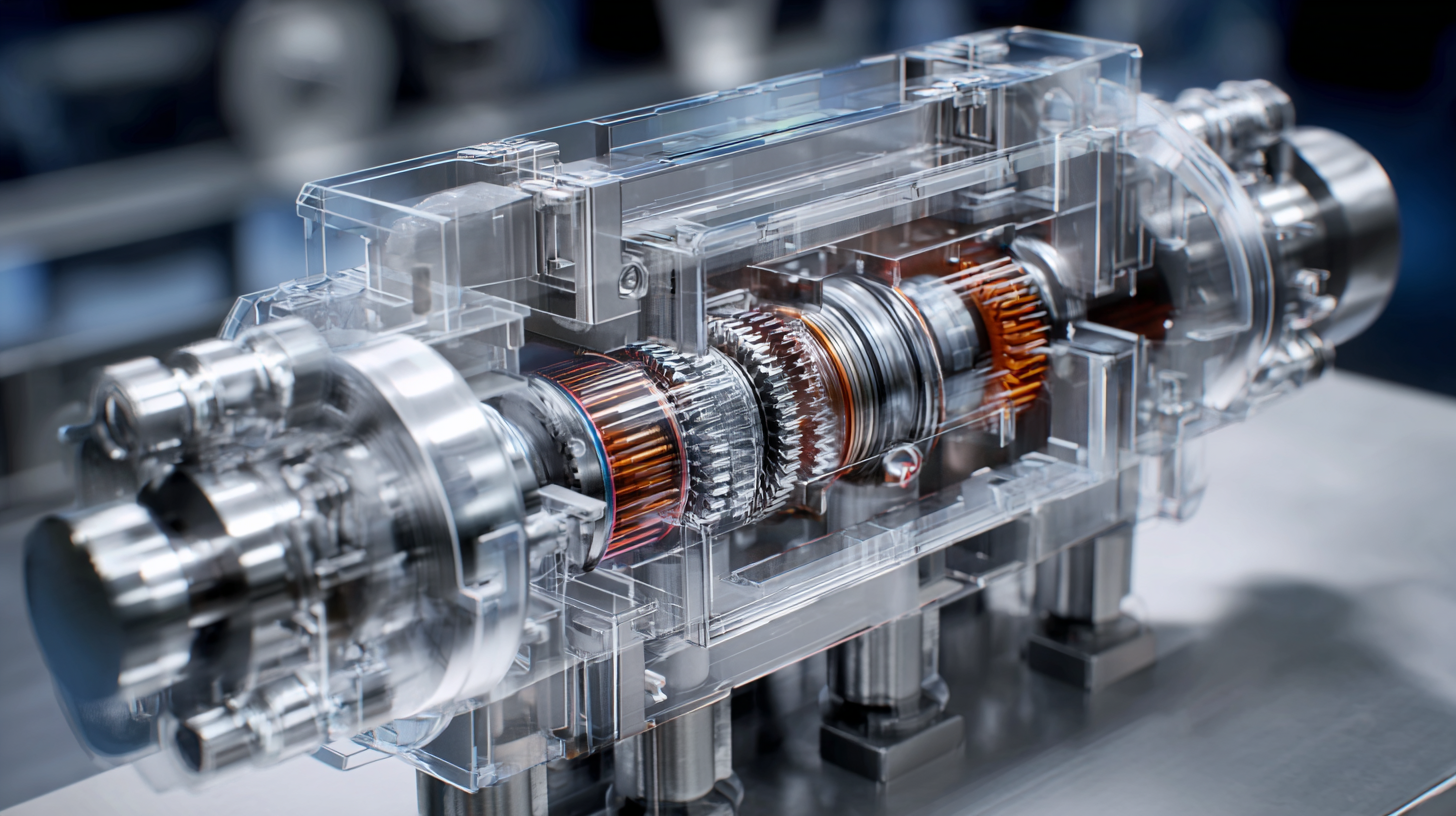

The field of fluid pump technology is undergoing significant transformations that enhance energy efficiency across various applications. Recent innovations focus on the integration of digital twin technology, which optimizes pump performance by allowing for real-time monitoring and predictive maintenance. For instance, studies reveal that the application of digital twins in drinking water networks has resulted in a 15-25% improvement in efficiency, significantly reducing operational costs and energy consumption.

Moreover, advancements in machine learning are being utilized to predict the performance of pumps more accurately, particularly in critical systems such as engine cooling. By implementing joint simulation techniques, industry reports indicate that the efficiency of both electronic fans and water pumps can potentially increase by over 20%. This is particularly crucial in applications involving high-performance computing and data centers, where even marginal gains in efficiency can lead to substantial savings on energy costs. These innovations not only contribute to operational efficiency but also align with broader sustainability goals, marking a pivotal shift in fluid pump technology toward greater energy performance.

Innovations in Fluid Pump Technology and Their Impact on Energy Efficiency

This chart illustrates the improvements in average pump efficiency over the past five years, showcasing how innovations in fluid pump technology have progressively enhanced energy efficiency.

Smart Pump Systems and Their Role in Energy Conservation

Smart pump systems represent a transformative leap in fluid pump technology, significantly enhancing energy conservation in various industrial applications. By incorporating advanced sensors, control algorithms, and real-time data analytics, these systems optimize performance based on the specific demands of the process. This adaptive operation reduces energy wastage and ensures that pumps operate only as required, minimizing unnecessary energy consumption.

Additionally, smart pump systems facilitate predictive maintenance, allowing for timely interventions that prevent efficiency losses and reduce downtime. By continuously monitoring performance metrics, operators can identify inefficiencies or wear before they become critical issues. The integration of these intelligent systems not only streamlines operations but also supports sustainability goals within industries, contributing to reduced carbon footprints. The move towards smart systems reflects a broader trend in engineering towards more responsive and efficient technologies, ultimately leading to significant energy savings and enhanced operational reliability.

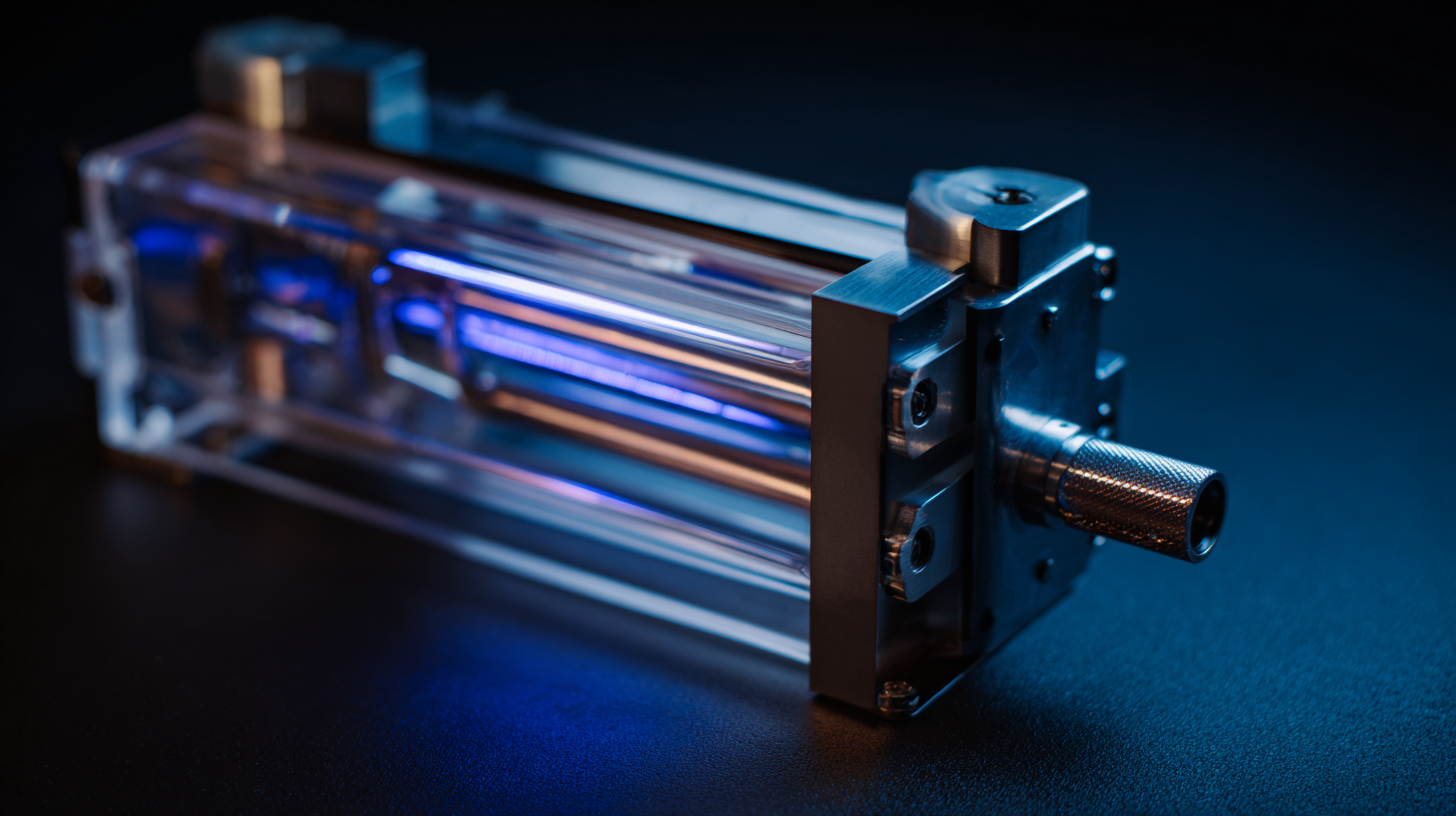

Advanced Materials in Pump Design: Enhancing Performance and Longevity

The advancement of materials in fluid pump design plays a pivotal role in enhancing performance and longevity. Modern pumps are increasingly utilizing advanced materials such as composite plastics, ceramics, and specialized alloys. These materials not only reduce the overall weight of the pumps but also increase their resistance to corrosion and wear. For example, the application of ceramic components in sealing and impellers leads to a significant reduction in maintenance needs, allowing pumps to operate for longer periods without degradation.

Innovative materials also contribute to energy efficiency by facilitating smoother fluid flow and minimizing energy loss due to friction. The development of nanostructured coatings can further optimize the surfaces of pump components, enhancing their hydrodynamic properties. This creates a more efficient pumping process, reducing energy consumption and operational costs. As manufacturers continue to explore these novel materials, the potential for improved pump designs that meet the growing demands for sustainability and efficiency becomes clearer, paving the way for a more energy-efficient future in fluid management systems.

The Impact of IoT on Fluid Pump Technology and Operational Efficiency

The integration of the Internet of Things (IoT) into fluid pump technology has revolutionized the industry, driving significant improvements in operational efficiency. According to a report by Grand View Research, the global IoT in the fluid pumping market is projected to reach $22.75 billion by 2026, growing at a CAGR of 14.5%. This growth is largely attributed to the enhanced capabilities provided by IoT, allowing for real-time monitoring and predictive maintenance. These innovations enable operators to identify and rectify potential issues before they escalate, reducing downtime and maintenance costs by up to 30%, as indicated in a study by McKinsey & Company.

Furthermore, the deployment of IoT solutions facilitates data-driven decision-making. By leveraging big data analytics, companies can optimize pump performance and improve energy efficiency. For instance, a recent report from the U.S. Department of Energy highlights that smart pumps equipped with IoT can lead to energy savings of 20-50% compared to traditional systems. This not only contributes to operational cost savings but also supports sustainability initiatives, making IoT a critical component in the evolution of fluid pump technology and operational efficiency. As industries strive for greater efficiency and lower energy consumption, the role of IoT will become increasingly vital.

Case Studies: Successful Implementations of Energy-Efficient Pump Solutions

Energy efficiency has emerged as a pivotal focus area for various sectors, particularly in the context of fluid pump technology. Between 2024 and 2025, Energy Service supported a multitude of projects aimed at enhancing energy efficiency in fleet operations and promoting the use of renewable energy solutions. These initiatives not only facilitate significant cost savings but also contribute to a sustainable future, highlighting the vital role energy-efficient pump solutions play in reducing carbon footprints.

Case studies illustrate the successful implementation of energy-efficient pumps in modernizing aging infrastructures. Retrofitting these systems can lead to remarkable outcomes, including a potential 12% reduction in global energy demand. This modernization not only results in financial savings running into billions but also fortifies buildings against climatic challenges, ensuring long-term resilience.

Tips: When considering energy-efficient upgrades, focus on selecting technologies that provide the best return on investment. Regular maintenance of fluid pump systems can also enhance performance and longevity. Embrace innovative solutions that align with sustainability goals, making a significant impact on both operational costs and environmental health.

Related Posts

-

Exploring the Future of Spark Plug Tools: Insights from the 2025 China Import and Export Fair

-

Unlocking Fuel Oil: Understanding Its Importance and Impact on Today's Energy Landscape

-

How to Choose the Right Air Filter Products for Your Home

-

Exploring Innovations in Fuel Pump Tool Technologies at the 138th Canton Fair 2025

-

Exploring the Future of Oil Pumps: Innovations and Efficiency in Modern Machinery

-

How to Choose the Right Oil Filter Adapter for Your Vehicle's Needs