Exploring the Latest Innovations in Fluid Pump Technology for Enhanced Efficiency

In recent years, the landscape of fluid pump technology has witnessed remarkable advancements driven by the need for enhanced efficiency and sustainability across various industries. As businesses increasingly prioritize energy conservation and operational excellence, the quest for innovative fluid pump solutions has become paramount. This exploration delves into the latest breakthroughs in fluid pump design and execution, highlighting key innovations such as smart pumping systems, advanced materials, and energy recovery mechanisms. By adopting cutting-edge technologies, manufacturers are not only improving the overall performance of fluid pumps but also addressing environmental concerns related to resource consumption and waste. This article will provide insights into the transformative developments in fluid pump technology, underscoring their significance in optimizing industrial processes and meeting the evolving demands of the market.

Emerging Trends in Fluid Pump Design for Optimal Performance

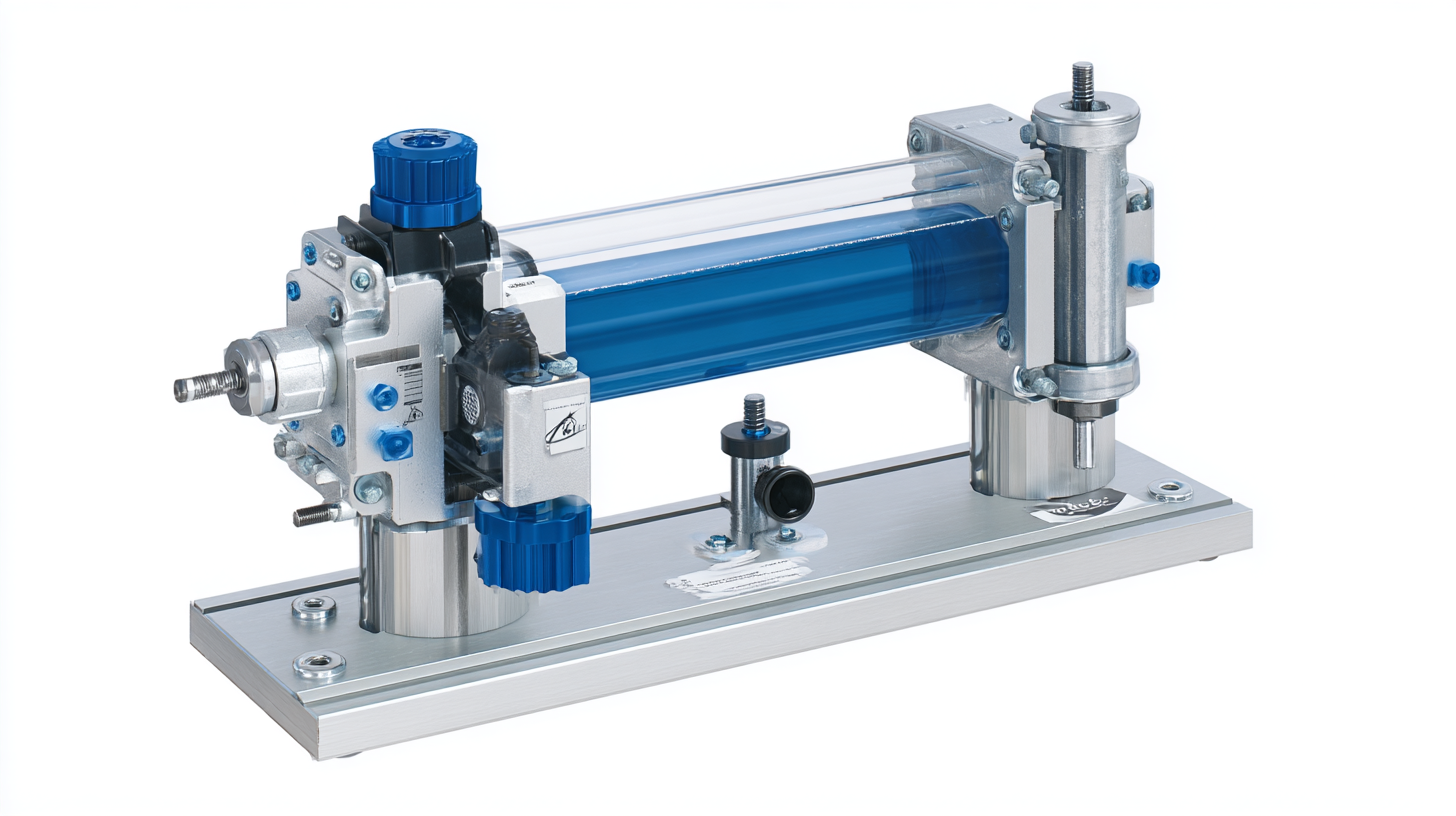

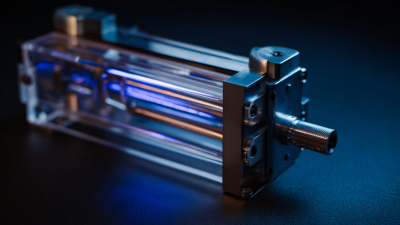

The field of fluid pump technology is undergoing significant transformations, driven by the need for optimal performance and enhanced efficiency. Emerging trends in fluid pump design focus on integrating advanced materials and smart technology to improve functionality and reliability. For instance, the adoption of lightweight, corrosion-resistant materials not only extends the lifespan of pumps but also reduces energy consumption, making them more environmentally friendly and cost-effective.

Another noteworthy trend is the incorporation of IoT (Internet of Things) capabilities into pump systems. By employing sensors and real-time data analysis, manufacturers can create pumps that automatically adjust their performance based on operational conditions. This responsiveness not only enhances energy efficiency but also minimizes downtime through predictive maintenance. Additionally, modular designs are gaining traction, allowing for easier customization and scalability, thus catering to the specific needs of diverse industries while ensuring peak operational efficiency.

Exploring the Latest Innovations in Fluid Pump Technology

Smart Technologies Revolutionizing Fluid Pump Operations

The latest advancements in fluid pump technology are significantly reshaping operational efficiency across various industries. With the integration of smart technologies, fluid pumps are becoming more intelligent, enhancing performance while minimizing energy consumption. Reports indicate that the global fluid pump market is expected to reach $68 billion by 2025, driven by innovations that deliver superior automation, predictive maintenance, and real-time monitoring.

A notable example of this transformation can be seen in cutting-edge cleaning machines, which utilize advanced heating technologies to optimize fluid dynamics. These machines, equipped with rapid-heating boilers, can heat water to temperatures exceeding 85°C, boosting cleaning efficiency and effectiveness through a dual pump system. This innovation not only improves cleaning outcomes but also aligns with rising environmental sustainability demands, as it enables the use of heated water to reduce the need for chemical cleaners.

Moreover, in sectors like oil and gas exploration, the push for technological enhancement continues unabated. Efficient drilling operations are now being supported by sophisticated pump systems designed to operate under high pressures and temperatures. This aligns with the industry's need to balance increased energy demands with stringent environmental regulations, showcasing how modern fluid pump innovations are pivotal for both operational growth and eco-friendly practices. As these technologies evolve, their impact on energy efficiency and productivity will only become more pronounced.

Exploring the Latest Innovations in Fluid Pump Technology for Enhanced Efficiency

| Innovation Type | Description | Benefits | Efficiency Improvement (%) | Implementation Time (months) |

|---|---|---|---|---|

| Smart Sensors | Integration of IoT sensors to monitor pump performance in real-time. | Increased reliability and reduced downtime. | 25% | 4 |

| Variable Frequency Drives (VFDs) | Control the pump speed based on demand, optimizing energy use. | Significant energy savings, reduced wear and tear. | 30% | 3 |

| Wear-Resistant Materials | Use of advanced materials to extend pump lifespan. | Lower maintenance costs and longer intervals between replacements. | 15% | 6 |

| Predictive Maintenance | Using data analytics to predict failures before they happen. | Avoids unexpected breakdowns, improves operational efficiency. | 20% | 5 |

| Energy Recovery Devices | Systems that recover and reuse energy from the pumping process. | Reduces energy consumption, lowers operational costs. | 35% | 8 |

Energy Efficiency Improvements in Modern Pump Systems

The relentless pursuit of energy efficiency in fluid pump technology has led to significant advancements in modern pump systems. Innovations such as variable frequency drives (VFDs) have transformed the way pumps operate, allowing for real-time adjustments to speed and flow rates based on demand. This not only optimizes performance under varying conditions but also significantly reduces energy consumption. Manufacturers are increasingly integrating these systems into their designs, ensuring that pumps operate at the most efficient levels throughout their lifecycle.

In addition to VFDs, enhanced materials and design innovations such as improved impeller shapes and advanced sealing technologies contribute to energy efficiency. These developments minimize hydraulic losses and reduce wear and tear, leading to longer lifespans and lower maintenance needs. Moreover, the incorporation of smart technology allows for better monitoring and diagnostics, providing operators with valuable data to make informed decisions regarding energy usage and system performance. As industries strive for sustainability, these energy-efficient pump systems play a crucial role in reducing operational costs and minimizing environmental impact.

Integrating IoT Solutions for Real-Time Pump Monitoring

The integration of IoT solutions in fluid pump technology is revolutionizing the industry by enabling real-time monitoring and enhanced efficiency. As the global market for smart and intelligent pumps is projected to reach $1.72 billion by 2025, the adoption of Internet of Things (IoT) applications is becoming increasingly significant. These solutions allow for seamless data collection and analysis, providing insights into performance and operational conditions. By leveraging advanced sensors and connectivity, businesses can preemptively identify maintenance needs and streamline operations, ultimately reducing downtime and operational costs.

Moreover, the asset tracking segment plays a critical role in this evolution, driven by innovations in technologies like RFID, GPS, and barcoding. These technologies facilitate precise monitoring of pump performance and location, offering companies a robust framework for asset management. As industries seek to optimize their fluid handling processes, the integration of IoT in pump technology not only enhances operational efficiency but also supports sustainability initiatives by minimizing waste and energy consumption. The anticipated compound annual growth rate of 7.5% in this sector reflects a growing recognition of the value of real-time data in driving performance and operational excellence in fluid management.

Sustainable Practices in Fluid Pump Manufacturing and Usage

Sustainable practices in fluid pump manufacturing and usage are crucial for minimizing environmental impact while enhancing operational efficiency. Recent industry reports indicate that approximately 30% of the energy consumed in industrial processes is attributed to fluid pumps. By adopting eco-friendly materials and technologies in pump design, manufacturers can significantly reduce their carbon footprint. For instance, implementing advanced materials such as lightweight composites not only lowers emissions during production but also improves the overall efficiency of the pump, leading to energy savings of up to 15%.

Incorporating smart technologies in fluid pump systems further enhances sustainability by optimizing energy use. Technologies like variable frequency drives (VFDs) allow for precise control of pump speed and flow rates, aligning energy usage with actual demand. According to a study by the American Society of Mechanical Engineers, using VFDs can result in energy savings of 25-50% in pumping applications. Adopting such technologies not only leads to cost savings but also supports a more sustainable operational model.

**Tips:** When selecting a fluid pump, consider energy-efficient models that are designed with sustainability in mind. Regular maintenance and monitoring of pump performance can also help identify inefficiencies, allowing for timely adjustments that further enhance energy savings. Additionally, explore options for recycling older pumps to minimize waste in manufacturing processes.

Related Posts

-

Unlocking Opportunities in Oil Filtration at China's 138th Canton Fair 2025: A Data-Driven Insight

-

Exploring the Future of Pump for Oil Innovations at the 138th Canton Fair 2025 in China

-

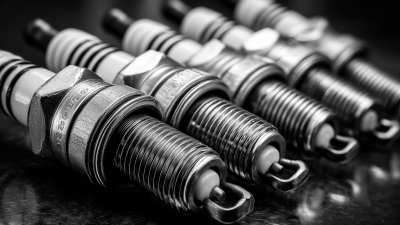

Unlock Your Engine's Potential: The Ultimate Guide to Choosing the Right Spark Plugs

-

Exploring the Innovations in Fluid Pump Technology and Their Impact on Energy Efficiency

-

How to Select the Right Fuel Oil for Your Industrial Needs

-

What are Spark Plugs and How Do They Impact Your Engine's Performance?