Ultimate Guide to Oil Filter Pump Tips for Better Performance and Maintenance

In the realm of automotive maintenance, the oil filter pump stands as a crucial component for ensuring optimal engine performance and longevity. Recognized expert in automotive engineering, Dr. Alan Perkins, emphasizes the importance of this component, stating, “Proper maintenance of the oil filter pump not only enhances engine efficiency but also prolongs its life.” As vehicles age, the significance of routine checks and effective oil management becomes paramount.

This ultimate guide offers valuable tips for optimizing the performance of your oil filter pump, ensuring that your vehicle runs smoothly and efficiently. With insights from industry leaders and practical maintenance strategies, we delve into the essential aspects of oil filter pump care that every vehicle owner should be aware of. From understanding the components to identifying common issues, this guide aims to empower drivers with the knowledge needed to maintain their engines effectively. Embrace the journey of vehicle care with an informed perspective on the vital role of the oil filter pump.

Understanding the Basics of Oil Filter Pumps for Optimal Use

Oil filter pumps play a crucial role in maintaining the performance of various machinery by ensuring that the oil circulated within the system remains clean and free from contaminants. At their core, these pumps are designed to filter out impurities from the oil, preventing damage and wear to engine components.

Understanding how oil filter pumps operate is vital for anyone looking to optimize their use and extend the lifespan of their equipment.

To utilize oil filter pumps effectively, it is important to familiarize oneself with their components and functions. Key elements include the pump itself, the filtration system, and the oil reservoir. Regular maintenance practices, such as checking the oil levels and replacing filters when needed, contribute significantly to the efficiency of the pump.

Moreover, monitoring the pressure and flow rates can help identify any issues before they escalate, ensuring that the machinery operates smoothly and remains reliable. By grasping the fundamentals of how oil filter pumps work, users can enhance their performance and achieve better maintenance outcomes.

Key Components of Oil Filter Pumps and Their Functions

Oil filter pumps play a crucial role in maintaining the efficiency and longevity of engines by ensuring that impurities are removed from the oil. At the heart of an oil filter pump system are several key components that contribute to its overall functionality. The pump itself is responsible for circulating oil throughout the engine, drawing it from the sump and pushing it through the oil filter. This filtration process is vital, as it prevents contaminants from causing wear and tear on engine parts, thereby enhancing performance.

Another essential component is the oil filter, which traps dirt, metal shavings, and other particulates. This filter typically contains a pleated paper element that maximizes surface area for trapping these unwanted substances. Additionally, the filter should be monitored and replaced regularly to ensure optimal flow rates and to prevent clogging, which can lead to decreased oil pressure and potential engine damage. Lastly, the pressure relief valve is a safety feature that opens to relieve excess pressure, protecting both the pump and the engine from damage caused by excessive oil buildup. Understanding these components and their functions will aid in better maintenance and increased performance of oil filter pumps.

Ultimate Guide to Oil Filter Pump Tips for Better Performance and Maintenance

| Component | Function | Maintenance Tips | Performance Impact |

|---|---|---|---|

| Oil Filter | Removes contaminants from oil | Replace every 3,000-5,000 miles | Improves engine life and efficiency |

| Pump Housing | Houses the oil pump mechanism | Check for leaks regularly | Ensures stable oil flow |

| Pump Motor | Drives the oil pump | Maintain proper lubrication | Directly affects pumping efficiency |

| Seals and Gaskets | Prevents oil leaks | Inspect for wear regularly | Ensures system integrity |

| Pressure Relief Valve | Regulates oil pressure | Test functionality during maintenance | Prevent oil system overpressure |

Essential Maintenance Tips for Prolonging Pump Lifespan

Maintaining the longevity of an oil filter pump requires a routine that emphasizes both regular inspection and proactive care. One of the most crucial aspects of maintenance is ensuring that the pump is kept clean and free from debris. Over time, dirt and particulates can accumulate, leading to decreased efficiency and potential damage. Regularly checking and replacing filters, as well as cleaning the pump components, can help avoid unnecessary wear and extend the life of the pump.

Another vital tip is to monitor the operating conditions of the pump closely. Ensure that it is functioning within the recommended pressure and temperature ranges, as excessive heat or pressure can cause catastrophic failures. Implementing routine checks of the oil level and quality is essential, as subpar oil can lead to increased friction and thermal breakdown. By adhering to a proactive maintenance schedule that includes timely oil changes and component inspections, you can significantly enhance the performance and lifespan of your oil filter pump.

Oil Filter Pump Performance Analysis

This chart illustrates the maintenance frequency of different oil filter pump models over a typical period. Regular maintenance is essential for prolonging the lifespan and performance of the pumps.

Troubleshooting Common Issues with Oil Filter Pumps

Oil filter pumps are essential for ensuring the efficient circulation of oil in various mechanical systems, yet they often encounter common problems that can hinder performance. One prevalent issue is the build-up of contaminants within the oil filter pump, which can lead to clogged filters and decreased flow rates. According to industry research, nearly 30% of pump failures can be attributed to inadequate filtration, underscoring the need for regular inspections and maintenance to ensure the longevity of the system.

Another common problem with oil filter pumps is the inability to maintain optimal pressure. This can be caused by air leaks or improper sealing, which allows air to enter the system and disrupts the pressure balance. The American Society of Mechanical Engineers (ASME) reports that proper sealing techniques can prevent up to 25% of pressure-related failures, emphasizing the importance of using high-quality seals and gaskets. Additionally, frequent monitoring of pressure gauges can aid in early detection of issues, allowing for timely corrective actions to be taken.

Moreover, improper installation is often to blame for subpar performance of oil filter pumps. A study conducted by the Hydraulic Institute indicates that almost 20% of pumps are misaligned during installation, leading to increased wear and decreased efficiency. Ensuring precise alignment and following manufacturer specifications can drastically reduce operational issues. Regular training for technicians on installation best practices is recommended to mitigate these complications and enhance the overall reliability of oil filter pump systems.

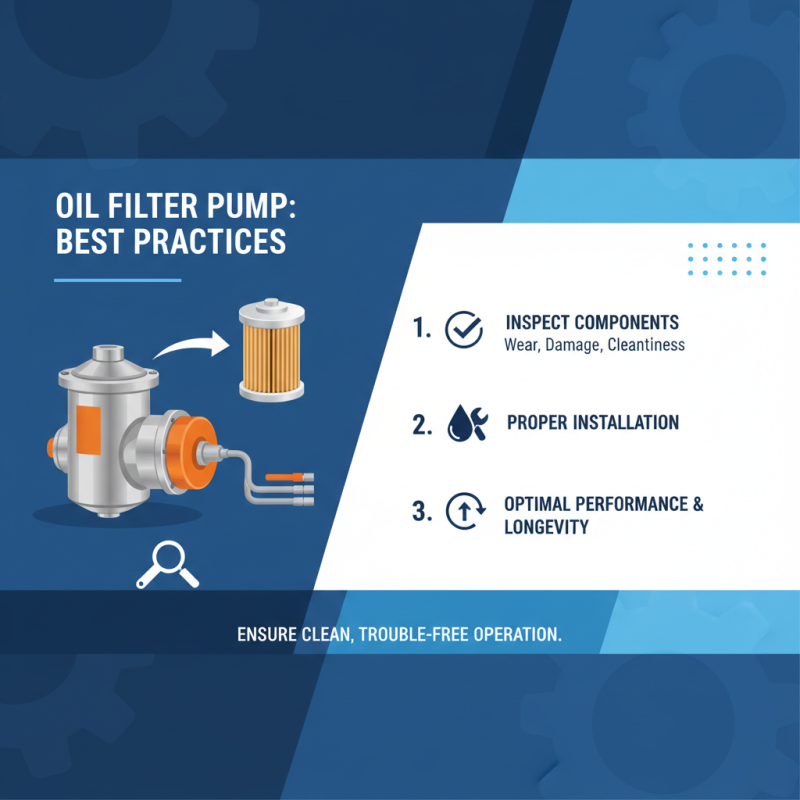

Best Practices for Oil Filter Pump Installation and Operation

When it comes to oil filter pump installation and operation, adhering to best practices is essential for ensuring optimal performance and longevity. First and foremost, it is crucial to thoroughly inspect all components before installation. This includes checking for any signs of wear or damage on the pump itself, the filter, and connecting hoses. Ensuring that all parts are clean and free from contaminants will help prevent operational issues later on.

Once the components have been inspected, the next step is proper installation. It’s important to follow the manufacturer’s guidelines carefully, paying attention to torque specifications and orientation. Sealants and gaskets should be used appropriately to prevent any leaks, which can lead to decreased efficiency and potential damage to the engine. Additionally, ensuring that the oil filter is correctly seated will help maintain proper oil flow and filtration.

During operation, regular monitoring is key. Keep an eye on the oil pressure and temperature readings to detect any irregularities early. Regular maintenance checks, including filter changes and oil assessments, will not only help sustain optimal performance levels but also prolong the life of the equipment. By following these best practices for installation and operation, users can ensure their oil filter pump remains efficient and reliable.

Related Posts

-

Unlock Your Engine's Potential: The Ultimate Guide to Choosing the Right Spark Plugs

-

How to Diagnose and Troubleshoot Common Fuel Pump Problems

-

Top 5 Benefits of Using Air Filter Oil for Optimal Engine Performance

-

How to Choose the Right Oil Filter Adapter for Your Vehicle's Needs

-

Unlocking Efficiency: The Best 2025 Oil Filter Tools for Every Mechanic's Needs

-

2025 How to Choose the Best Air Filter Oil for Your Vehicle Maintenance