2026 Top Strategies for Effective Filter Oil Maintenance and Usage

The importance of filter oil cannot be overstated in various industrial applications. Proper maintenance and usage of filter oil can enhance performance and extend equipment life. Yet, many overlook its significance.

In 2026, businesses should prioritize effective strategies for filter oil management. Effective techniques include regular monitoring of oil quality and timely replacements. Equipment operators must be trained to identify signs of oil degradation.

There is room for improvement in how organizations handle filter oil. Many face challenges in maintaining optimal oil conditions. Understanding the need for better practices can lead to significant advancements in operational efficiency. A proactive approach ensures that every drop of filter oil contributes to smoother operations.

Overview of Filter Oil and Its Importance in Maintenance

Filter oil plays a critical role in maintaining equipment performance. It helps remove contaminants, ensuring smooth operation. Effective filter oil usage can prevent costly breakdowns. When oil becomes dirty, it can lose its ability to lubricate properly. This often leads to accelerated wear and tear on machinery.

Regular monitoring is essential for effective filter oil maintenance. Users should schedule frequent inspections to check oil clarity and viscosity. If the oil appears dark or gritty, it may need replacement. These are signs that your equipment is not getting the protection it needs. Remember, neglecting filter oil can result in larger issues that are more expensive to fix.

Many users overlook the importance of proper oil disposal. Disposing of used filter oil improperly can lead to environmental hazards. It’s critical to use designated disposal methods. Awareness of these factors can greatly enhance maintenance strategies. Strive to improve your understanding of filter oil’s role in overall machinery health. Openness to continuous learning can lead to more effective maintenance practices.

2026 Top Strategies for Effective Filter Oil Maintenance and Usage

| Strategy | Description | Benefits | Frequency of Maintenance |

|---|---|---|---|

| Regular Filter Checks | Inspect filter oil levels and condition frequently. | Prevents contamination and operational failures. | Weekly |

| Proper Disposal | Dispose of used filter oil following regulations. | Reduces environmental impact and ensures compliance. | After each oil change |

| Oil Filtration Systems | Implement systems to filter oil continuously. | Enhances oil life and machine efficiency. | Continuous |

| Temperature Control | Monitor and maintain oil temperature to optimal levels. | Prevents thermal breakdown and extends oil life. | Daily |

| Regular Sampling | Test oil samples for contamination and wear particles. | Identifies potential issues before they escalate. | Monthly |

Key Factors Influencing Filter Oil Performance and Longevity

Effective filter oil performance and longevity depend on critical factors. Quality is one of the most significant elements. According to the Filtration Society's report, poor-quality oil can reduce filter life by up to 50%. It's essential to choose oils that meet industry standards. This ensures better filtration and longer service intervals.

Temperature also plays a crucial role. Filter oils degrade faster at higher temperatures. The Society of Automotive Engineers emphasizes that operating above the recommended range can compromise oil efficacy. Regular monitoring of temperature can help mitigate issues. Using appropriate cooling systems is vital.

Another aspect to consider is contamination. Particulate matter can rapidly degrade filter performance. Studies show that filters exposed to high levels of contaminants can fail within weeks. Regular maintenance checks and timely oil changes are necessary. Failure to address these factors can lead to costly breakdowns. While some may neglect these elements, they are foundational for filter oil longevity.

2026 Top Strategies for Effective Filter Oil Maintenance and Usage

Best Practices for Regular Filter Oil Inspection and Monitoring

Regular inspection of filter oil is crucial for optimal performance. Studies show that 30% of systems encounter issues due to neglecting oil quality. Monitoring oil color, viscosity, and contamination levels can prevent costly failures. Using simple tools like dipsticks and visual checks can provide early warnings of degradation.

Tips: Schedule routine checks every 200 hours of operation. Regularly measure the oil temperature to ensure it's within the recommended range. This will help maintain efficiency.

Many users overlook oil changes until it's too late. Data indicates that outdated filter oil can lead to a 20% drop in filtration efficiency. Investing time in consistent monitoring is essential. Not all operations run smoothly, and acknowledging that can improve your maintenance practices.

Tips: Keep a log of oil inspection findings. This can identify patterns over time. Small changes can lead to significant improvements in your system's reliability. Remember, proactive maintenance saves time and money in the long run.

Effective Methods for Filter Oil Replacement and Disposal

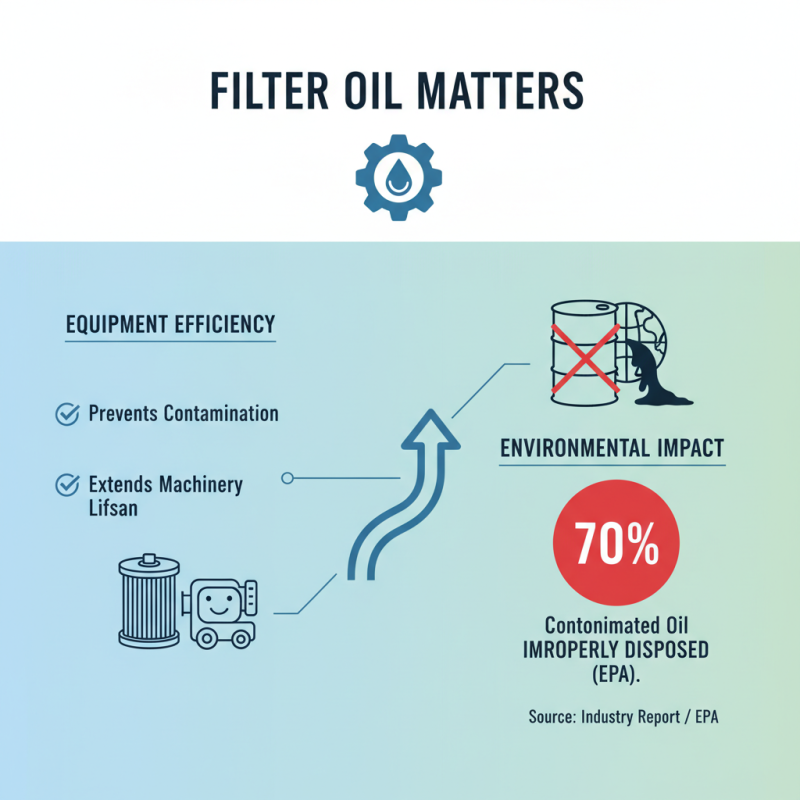

Filter oil plays a crucial role in maintaining equipment efficiency. Regular replacement helps prevent contamination and extends the lifespan of machinery. A recent industry report highlights that improper disposal of filter oil can lead to environmental hazards. In fact, nearly 70% of contaminated oils are improperly disposed of according to the EPA.

Effective methods for filter oil replacement focus on timing and technique. Experts recommend changing filter oil every 1,000 to 3,000 operational hours. This frequency depends on usage conditions. Additionally, trained personnel should handle the replacement to minimize accidental spills. Oil filtration systems can capture particulate matter. Yet, leftover oil often ends up in landfills. Some facilities still lack proper recycling protocols.

Disposing of filter oil requires attention. Only specific centers accept used oil. Many users overlook local regulations. Chemical properties of old filter oils can harm ecosystems if not handled properly. Awareness and compliance can lead to significant improvements. The industry must address these challenges to protect resources and ensure sustainability.

Innovative Technologies Enhancing Filter Oil Efficiency and Usage

Innovative technologies play a crucial role in enhancing filter oil efficiency. According to a recent industry report, the use of advanced filtration systems can improve oil lifespan by up to 40%. Technologies like electrostatic filtration remove finer contaminants, extending the life of the oil and equipment. This not only reduces costs but also minimizes waste.

However, innovation in this field is not without challenges. Many facilities struggle to implement these technologies effectively due to outdated equipment or insufficient training. Consistent maintenance schedules become critical. Surprisingly, a study showed that 30% of operators neglect routine checks on oil quality. Regular monitoring could significantly enhance system performance.

The integration of real-time monitoring systems can also yield benefits. Data from a survey indicated that companies using IoT solutions report a 25% reduction in unexpected downtime. Yet, the adoption of such systems remains slow. Many organizations hesitate to invest in new technologies without clear evidence of ROI. The path forward requires addressing these barriers to maximize filter oil efficiency.

Related Posts

-

Why You Should Always Choose the Best Oil Filter for Your Vehicle's Performance

-

How to Choose the Best Spark Plug Tools for Your Vehicle Maintenance

-

2025 How to Choose the Right Air Tool Oil for Optimal Performance

-

How to Choose the Right Oil Pumps for Your Industrial Needs

-

Ultimate Guide to Oil Filter Pump Tips for Better Performance and Maintenance

-

Top 10 Benefits of Using a Pneumatic Pump in Various Applications